Full HRSG Inspection

Nooter/Eriksen’s experienced inspection staff can perform a thorough internal and external inspection of your plant’s HRSG equipment. By identifying preventative maintenance issues, as well as long term risks or underlying causes for existing issues, Nooter/Eriksen can help plants avoid the risk of costly downtime resulting from forced outages. Our experience, knowledge and expertise in all things HRSG allows our inspection team to assist plant personnel in identifying and prioritize the repair of the most pressing issues during limited maintenance windows as well as plan long term repairs, upgrades and modifications that will maximize HRSG reliability and longevity. Nooter/Eriksen’s inspection staff will review and document all major issues and present this information in a detailed report in real time while onsite.

Performance Assessment

Whether driven by changing market conditions, demand or efficiency, the way a plant operates in today’s environment may not reflect those for which it was originally designed. That is okay! The changes in demand can be as unique as the environments in which they operate, and Nooter/Eriksen is ready to help you meet those challenges. The first step is to understand the new demands on the HRSG equipment and what that means for your specific circumstances.

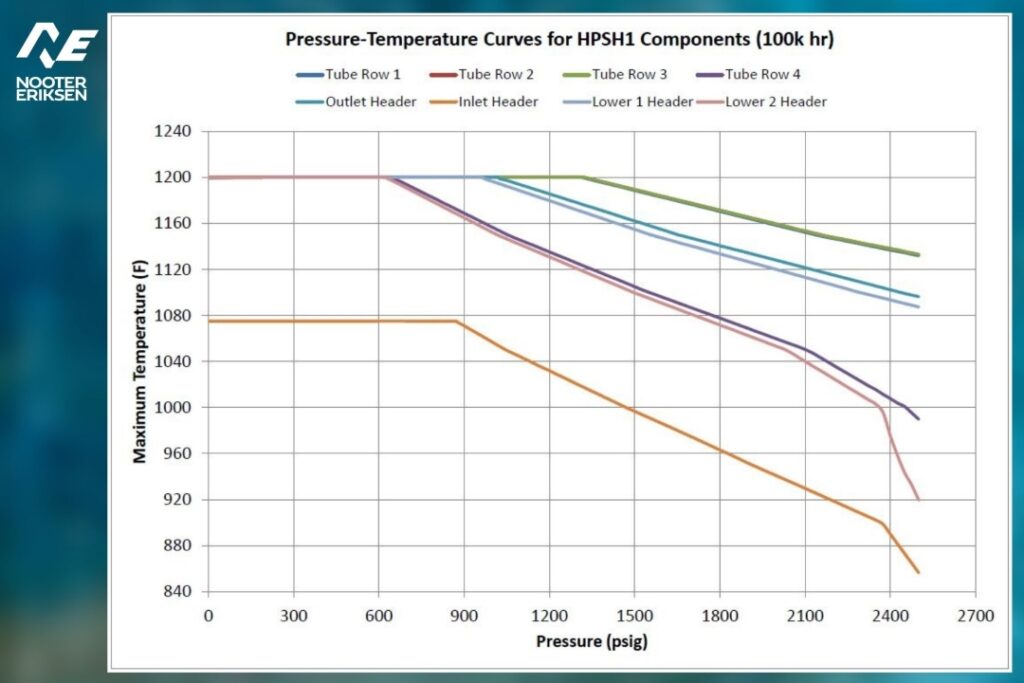

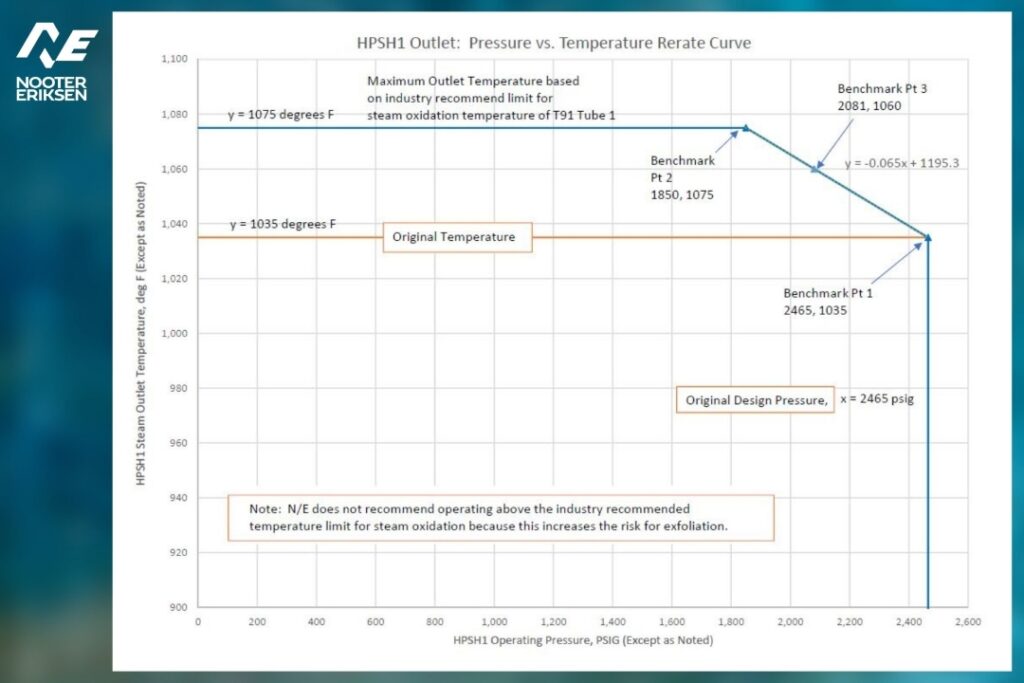

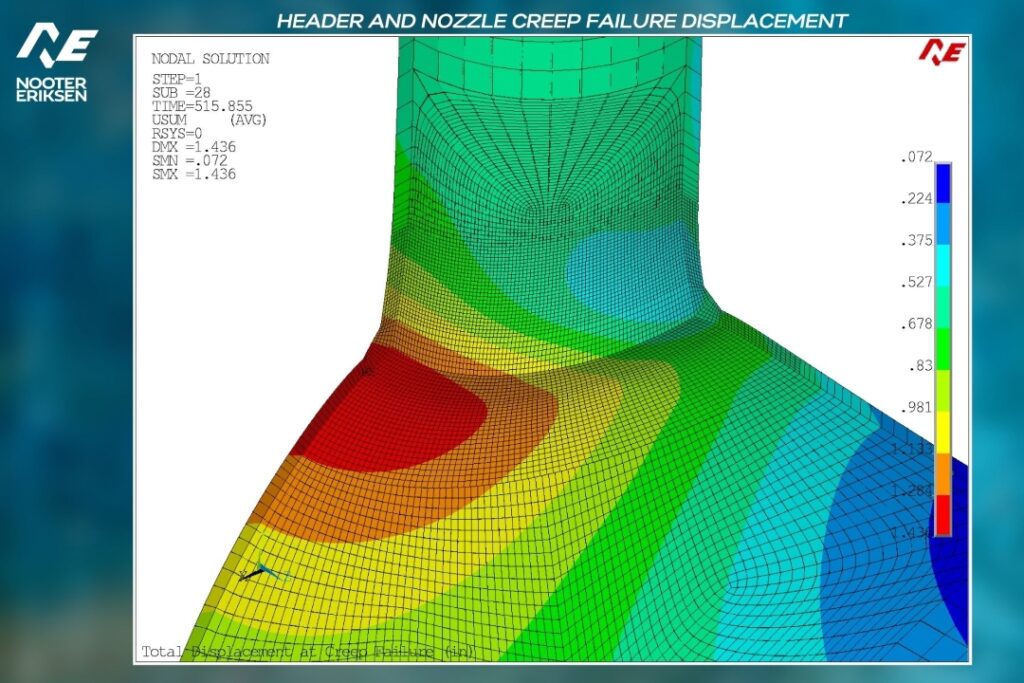

Transitioning from base load to cyclic service, CT upgrades, low load operation, part load firing, and boiler rerates are just some examples of changes that impact the operating conditions imposed on the HRSG. In the event the HRSG is operated under these different conditions, certain components of the HRSG may be operating at significantly reduced margins or even above the original design conditions. Our experienced engineering staff can perform a detailed evaluation of any HRSG and advise about needed modifications to find the best possible overall solution. This provides assurance to owners that any changes can be accomplished without increased risk of failure from the HRSG operating outside its original design conditions.

Combustion Turbine Upgrade

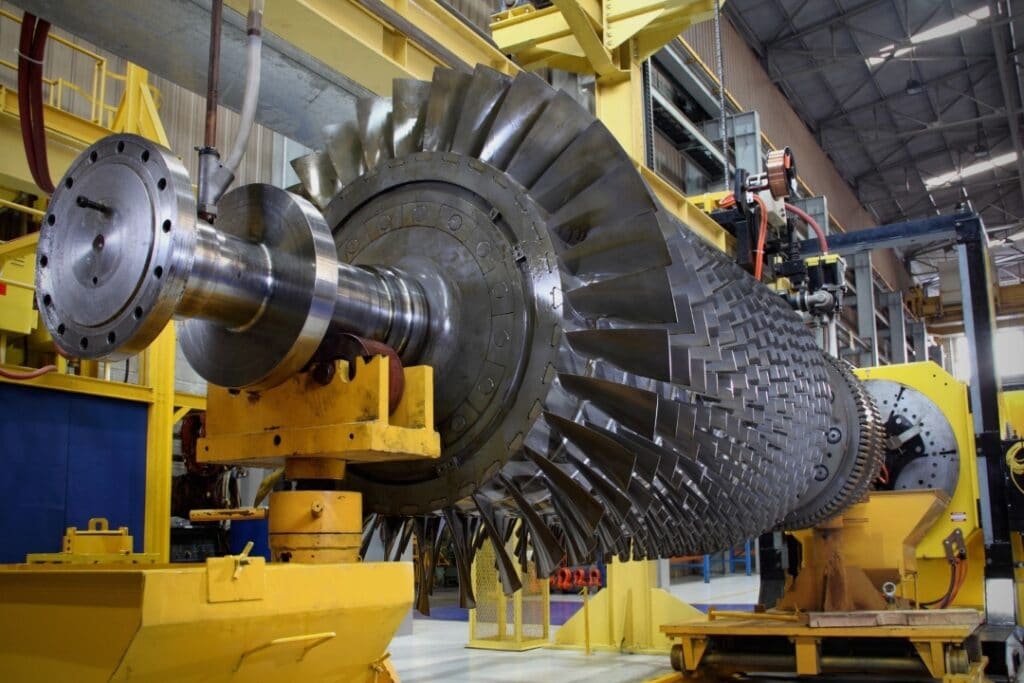

One of the most common changes made at plants across the combined cycle industry is periodic upgrades to the Combustion Turbines to increase efficiency and output. While this can be a great thing for a plant, an often overlooked, but critical consequence of such a change is the effect on the downstream equipment. Most notably is its effect on the HRSG and by extension the steam turbine.

Performance output obtained from combustion turbine upgrades can often be limited by the existing HRSG design limits, carryover and steaming capacity in the drums, spraying limits in desuperheaters, or pressure safety valve set points. By working in concert with the plant operators and CT design team, Nooter/Eriksen will create the needed engineering models to complete a comprehensive evaluation on the impacts of the proposed combustion turbine performance changes to the HRSG production and design of the mechanical components. This is all done with the goal of assisting the plant in understanding whether the benefit of the combustion turbine upgrade will be limited by the design of the HRSG or if it will affect steam production in a way that could impact the downstream Steam Turbine. Included in the evaluation report, will be a listing of potential HRSG improvements to maximize the performance of the combustion turbine upgrade and Nooter/Eriksen can work with the plant to implement turn-key solutions that will result in the best overall plant production.

Burner Assessment

Gas turbine exhaust flow distribution and duct burner fuel gas flow distribution are critically important in duct burner design and operation. Good flow distribution is required to minimize emissions, ensure flame stability, minimize flame length, and to protect against flame impingement on downstream components. Exhaust and flue gas distribution can have a significant effect on the temperature variation after the burner. Large temperature variations can result in locally overheated superheater and reheater components. Nooter/Eriksen can perform an engineering study to evaluate the HRSG design and components in order to ensure optimal temperature distribution is achieved.